Screen printing is an ancient style of art that dates back to the Song Dynasty in China. Later the printing technique spread to other Asian countries and evolved with time with newer methods. Western Europe was introduced to Screen printing sometime in the late 18th century.

Traditionally the process of screen printing was known as silk screen printing as in the earlier day; silk was used in the process. It was also referred to as serigraph printing or serigraphy. Today, synthetic threads or polyester are used in place of silk, and stainless steel is employed to the screen printer. Read on to learn more about the technique behind.

The Screen Printing Technique

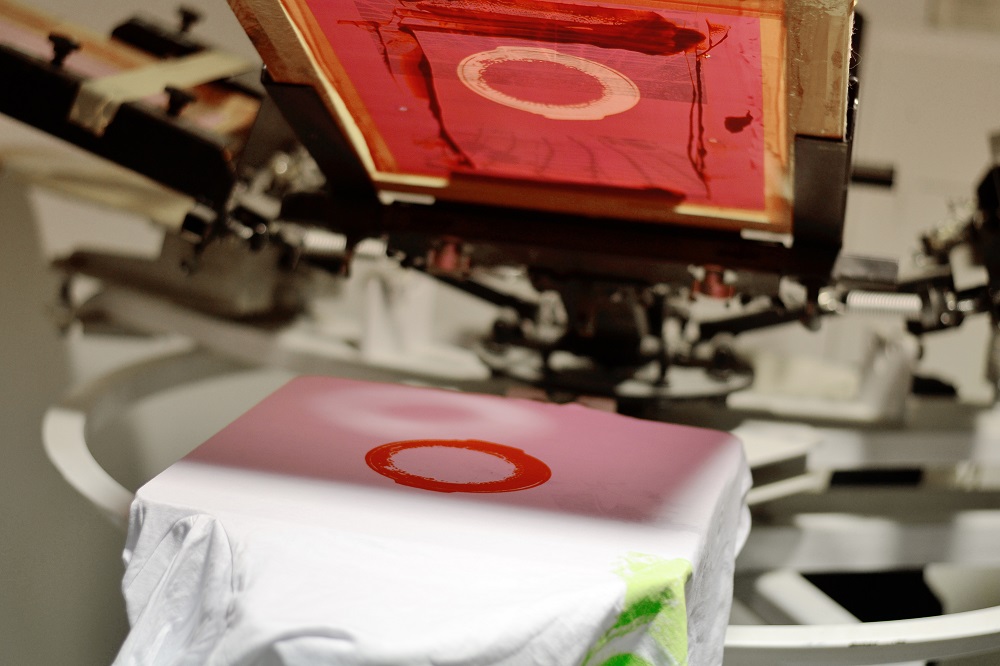

The printing technique makes use of a mesh to add ink ingot a substrate and only in the permeable areas. The ink doesn’t enter those areas that have been made impermeable with the help of a blocking stencil. The open mesh apertures are run over with the desired ink colour with the help of a blade or squeegee. The artisan moves the squeegee across the stencil to deposit the colour uniformly into the substrate. Once the desired colour has been transferred into the fabric or the substrate, a different stencil screen is used to create a multi-coloured design. However, one has to be careful when choosing the design, colours and placing the screens to get that perfect result.

Different Types of Ink Used in Screen Printing

There are different types of inks used in screen printing, and different inks render different effects. One of the most common inks used in the printing is Plastisol which is a suspension of PVC particles. As the ink creates an excellent image clarity, it is popularly used for printing garments. Discharge Inks are used to lighten the effect of the colours while the water-based inks are used for higher penetration of the ink in the fabric. One can create complicated designs with the help of screen printing. The more the number of screens and the higher the number of colours, the more complicated is the design. And there are dozens of inks to pick from, and one can literally create any possible design, no matter how complicated.

Customised Screen Printing

Today there are different kinds of screen printing that are customised based on individual needs and preferences. Custom screen printing is used in different fields and industries for both non-profits and business purposes. Here are just a couple of ideas where the customized printing is used.

- In accessories – Screen printing is being used to print accessories such as bucket hat, baseball cap, beanie or tote bag and create a customised look.

- Personalized apparel – One can easily create personalized hoodies, jackets, sweatshirts, shirts, polo’s, shorts, underwear and more.

- In the world of Advertising– It is easy to place the name of your company or logo on banners, yard signs, flyers, stickers with the help of screen printing.

- For Business items – One can get the office supplies and items such as banners, calendars, flash drives, iPad cases and even more with screen printing.

- Custom-made Party supplies – It would be great fun to throw a party with customised items and other party supplies. Screen printing technology makes it a lot simpler.

- Specialised Promo items – For those looking forward to luring their potential customers, they can spread a good word about their company by gifting them customized keychains, lanyards, chocolates, pens, pencils and a lot more.

You can use this Color Separation software to create your artwork for screen printing.

So, when it comes to custom screen printing, the options are indeed endless. One can create just the design they are looking for and design customised accessories, apparel, office item or promo items to run their organization or boost their business.

Subscribe to our RSS-feed and follow us on Twitter to stay in touch.

Discover more from Life and Tech Shots Magazine

Subscribe to get the latest posts sent to your email.