Hydraulic paper cutting machines are a vital tool in the printing and paper manufacturing industry. These machines offer precise and efficient cutting capabilities, making them indispensable for businesses that deal with large volumes of paper. In this article, we will delve into the inner workings of hydraulic paper cutting machines, providing a comprehensive understanding of how they operate and their advantages over other cutting methods.

Understanding the basics of hydraulic systems

Before we dive into the intricacies of hydraulic paper cutting machines, it is essential to grasp the fundamentals of hydraulic systems. A hydraulic system relies on the transmission of force through a fluid. In the case of paper cutting machines, this fluid is typically hydraulic oil. The oil is stored in a reservoir and pumped into the hydraulic system, where it generates pressure to power various components.

Components of a hydraulic paper cutting machine

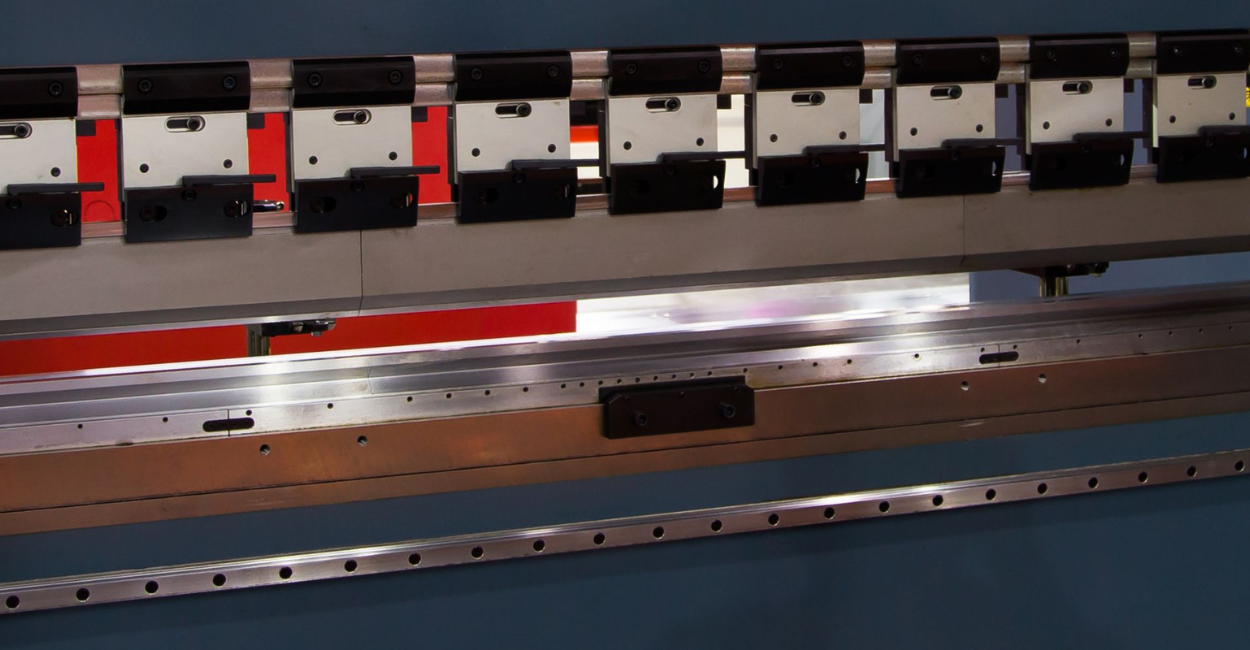

To comprehend how a hydraulic paper cutting machine functions, it is necessary to familiarize ourselves with its key components. The primary components of a hydraulic paper cutting machine include a hydraulic pump, hydraulic cylinder, cutting blade, and control panel. The hydraulic pump is responsible for pressurizing the hydraulic fluid, which is then transferred to the hydraulic cylinder. The hydraulic cylinder converts the fluid pressure into mechanical force, enabling the movement of the cutting blade. The control panel allows operators to regulate the cutting process, ensuring precision and safety.

Step-by-step guide on how a hydraulic paper cutting machine works

Now that we have a basic understanding of hydraulic systems and the components of a hydraulic paper cutting machine, let us explore the step-by-step process of how these machines operate.

- Preparation: To begin, the operator prepares the paper stack by aligning it properly on the cutting bed. This ensures accurate and consistent cuts.

- Positioning: Once the paper stack is properly aligned, the operator adjusts the back gauge of the machine, setting the desired cutting length. The back gauge ensures uniformity in the size of the cut pieces.

- Pressurization: With the paper stack and cutting length set, the operator initiates the hydraulic pump, which pressurizes the hydraulic fluid. The pressure generated is then transferred to the hydraulic cylinder.

- Cutting: As the hydraulic cylinder receives the pressurized fluid, it extends, causing the cutting blade to descend onto the paper stack. The cutting blade slices through the paper with precision, thanks to the mechanical force exerted by the hydraulic system.

- Release and Reset: Once the cut is complete, the hydraulic cylinder retracts, lifting the cutting blade away from the paper stack. The operator can then remove the cut pieces and prepare the machine for the next cutting cycle.

Advantages of using hydraulic paper cutting machines

Hydraulic paper cutting machines offer several advantages over alternative cutting methods, making them the preferred choice for many businesses.

Firstly, hydraulic paper cutting machines provide unparalleled precision. The mechanical force generated by the hydraulic system ensures clean and accurate cuts, resulting in a professional finish for every piece of paper. This precision is particularly crucial for industries that require high-quality output, such as printing and packaging.

Secondly, hydraulic paper cutting machines are incredibly efficient. The power of hydraulic systems allows for swift cutting speeds, reducing production time and increasing overall productivity. Additionally, the automation features found in modern hydraulic paper cutting machines further streamline the cutting process, minimizing human error and maximizing efficiency.

Moreover, hydraulic paper cutting machines are versatile, capable of handling various types of paper and paper-related materials. Whether it is delicate tissue paper or thick cardboard, hydraulic systems can adapt to different materials and thicknesses, ensuring consistent and precise cuts across the board.

Safety considerations when operating a hydraulic paper cutting machine

While hydraulic paper cutting machines offer numerous benefits, it is essential to prioritize safety when operating these powerful machines. Here are a few safety considerations to keep in mind:

- Training and Familiarization: Operators should receive proper training on the operation and safety protocols of hydraulic paper cutting machines. Understanding the machine’s components, emergency procedures, and safe operating practices is crucial to prevent accidents.

- Protective Equipment: Operators must wear appropriate personal protective equipment (PPE), such as gloves and safety glasses, to safeguard themselves from potential hazards during the cutting process. Additionally, the machine should be equipped with safety features like guards and emergency stop buttons.

- Regular Maintenance: Regular maintenance and inspections are vital to ensure the machine is in proper working condition. Checking for any leaks, worn-out components, or malfunctions can prevent accidents and maintain the machine’s optimal performance.

Maintenance tips for hydraulic paper cutting machines

To prolong the lifespan and efficiency of hydraulic paper cutting machines, regular maintenance is essential. Here are some maintenance tips to keep in mind:

- Fluid Checks: Regularly inspect the hydraulic fluid level and quality. Ensure that the fluid is clean and free from contaminants. If necessary, replace or refill the fluid following the manufacturer’s guidelines.

- Component Lubrication: Proper lubrication of the machine’s moving parts is crucial to prevent friction and ensure smooth operation. Follow the manufacturer’s recommendations for lubrication intervals and use appropriate lubricants.

- Blade Sharpening: Over time, the cutting blade may become dull. Periodically check the blade’s sharpness and sharpen or replace it as needed. A sharp blade ensures clean cuts and minimizes strain on the hydraulic system.

Comparing hydraulic paper cutting machines with other cutting methods

While hydraulic paper cutting machines excel in many areas, it is worth considering how they compare to alternative cutting methods. Two commonly used cutting methods are mechanical cutting and laser cutting.

Mechanical cutting, which involves the use of manual or electrically-driven blades, is a traditional approach that offers simplicity and affordability. However, it lacks the precision and speed of hydraulic paper cutting machines. Mechanical cutting is often suitable for low-volume cutting requirements or less demanding applications.

On the other hand, laser cutting utilizes a high-powered laser to cut through materials. Laser cutting offers exceptional precision, especially for intricate designs. However, it can be costly, and the heat generated during the process may affect certain materials. Hydraulic paper cutting machines strike a balance between precision and affordability, making them a versatile choice for many businesses.

Conclusion: The future of hydraulic paper cutting machines

As we have explored the intricacies of hydraulic paper cutting machines, it is evident that they play a crucial role in the printing and paper manufacturing industry. With their precision, efficiency, and versatility, hydraulic paper cutting machines continue to be a preferred choice for businesses worldwide.

Looking ahead, advancements in technology may further enhance the capabilities of hydraulic paper cutting machines. Automation features, improved safety mechanisms, and increased cutting speeds are just a few areas where future developments may occur. As businesses strive for efficiency and cost-effectiveness, hydraulic paper cutting machines will undoubtedly remain at the forefront of the industry.

In conclusion, understanding how hydraulic paper cutting machines work provides valuable insights into their benefits and applications. By harnessing the power of hydraulic systems, these machines offer the perfect balance between precision, efficiency, and versatility in the world of paper cutting.

Discover more from Life and Tech Shots Magazine

Subscribe to get the latest posts sent to your email.